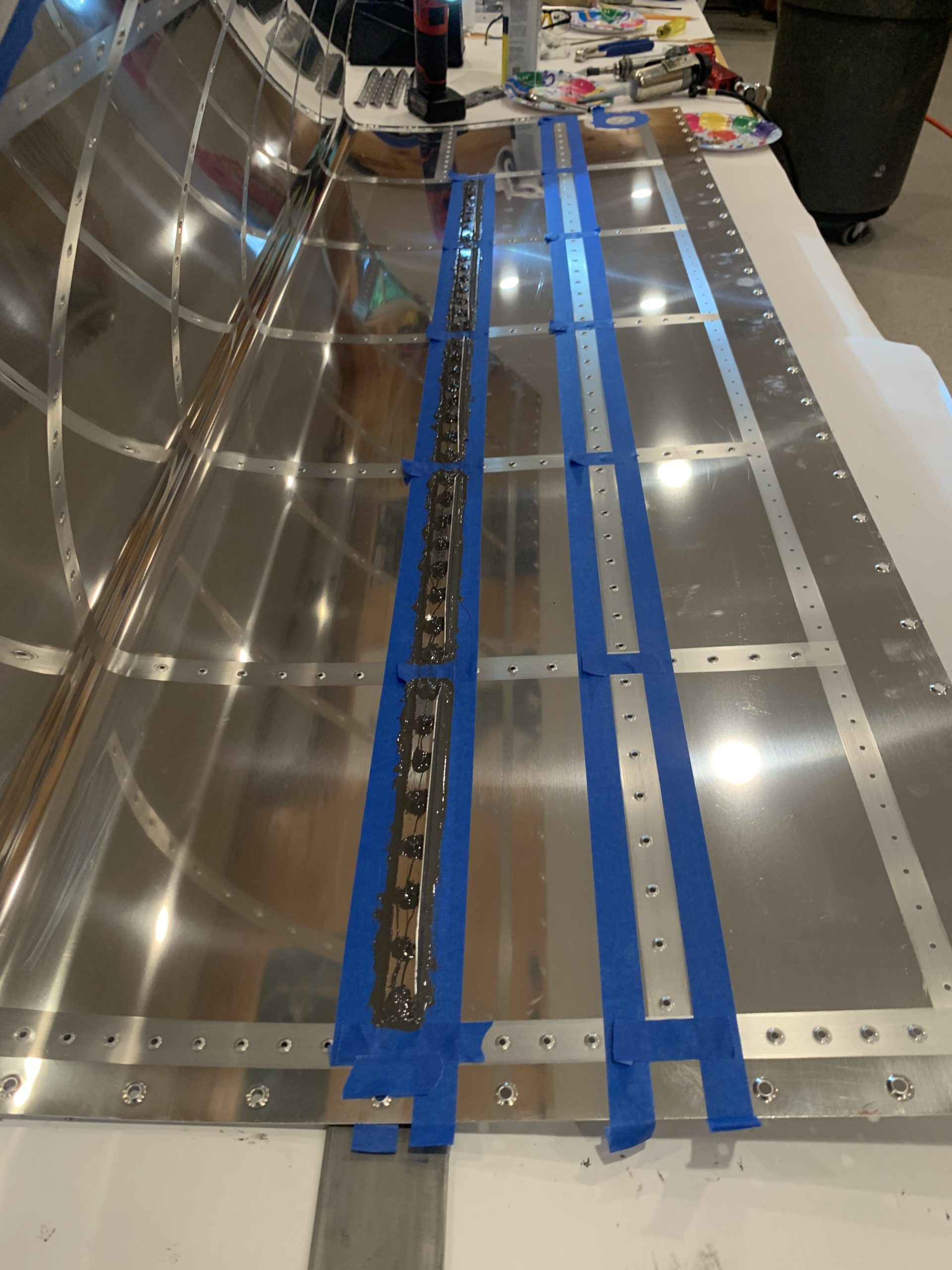

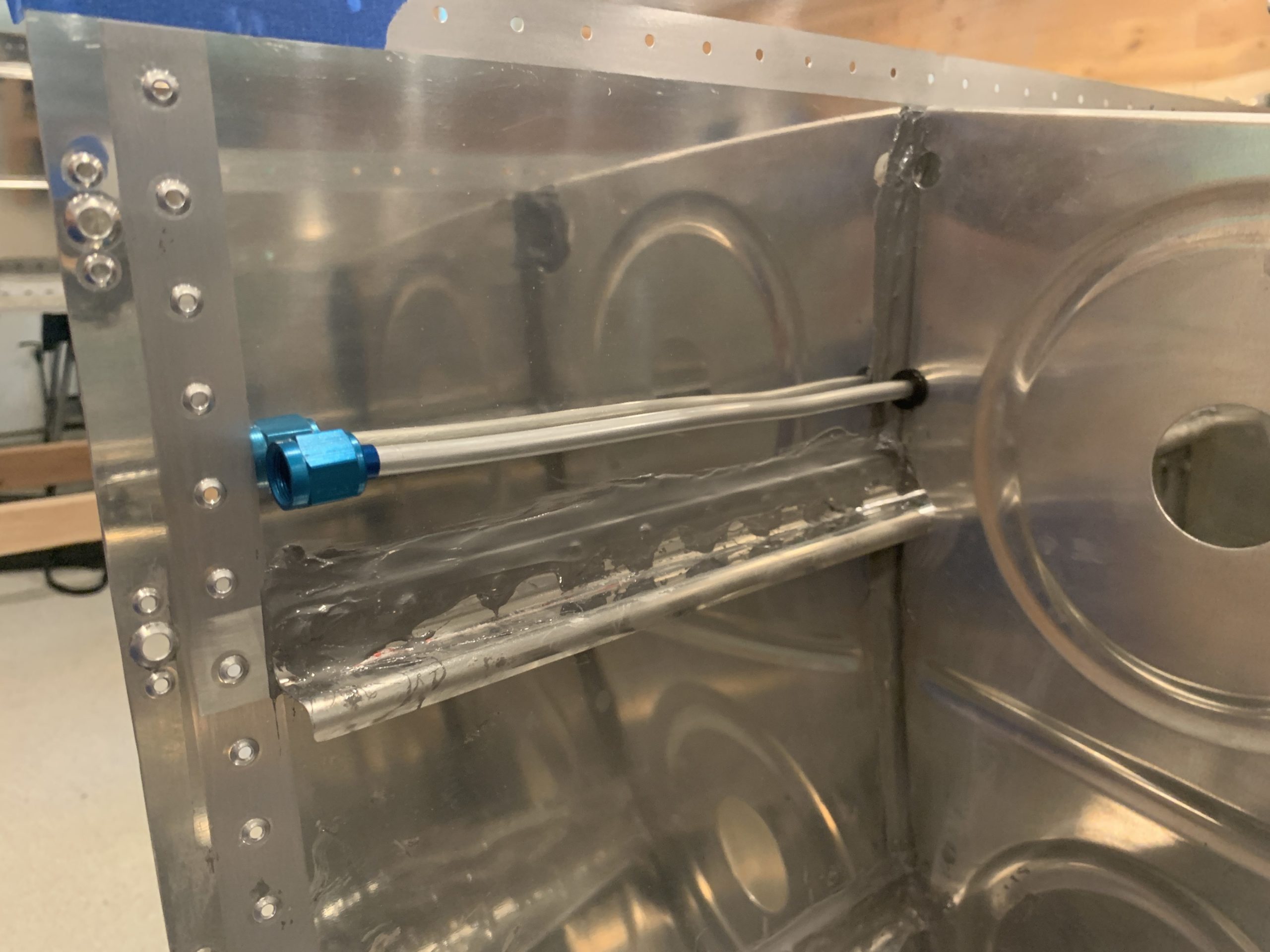

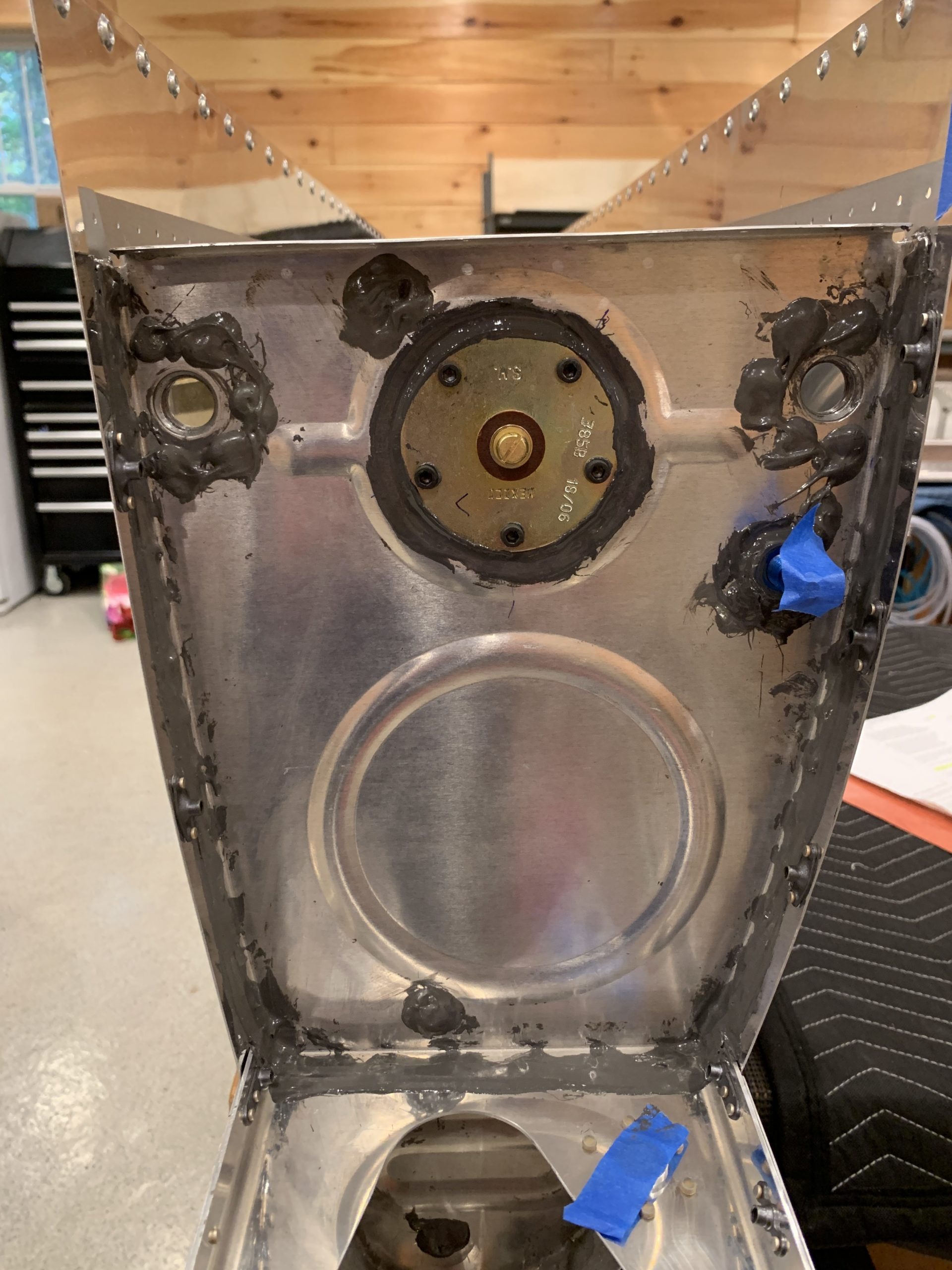

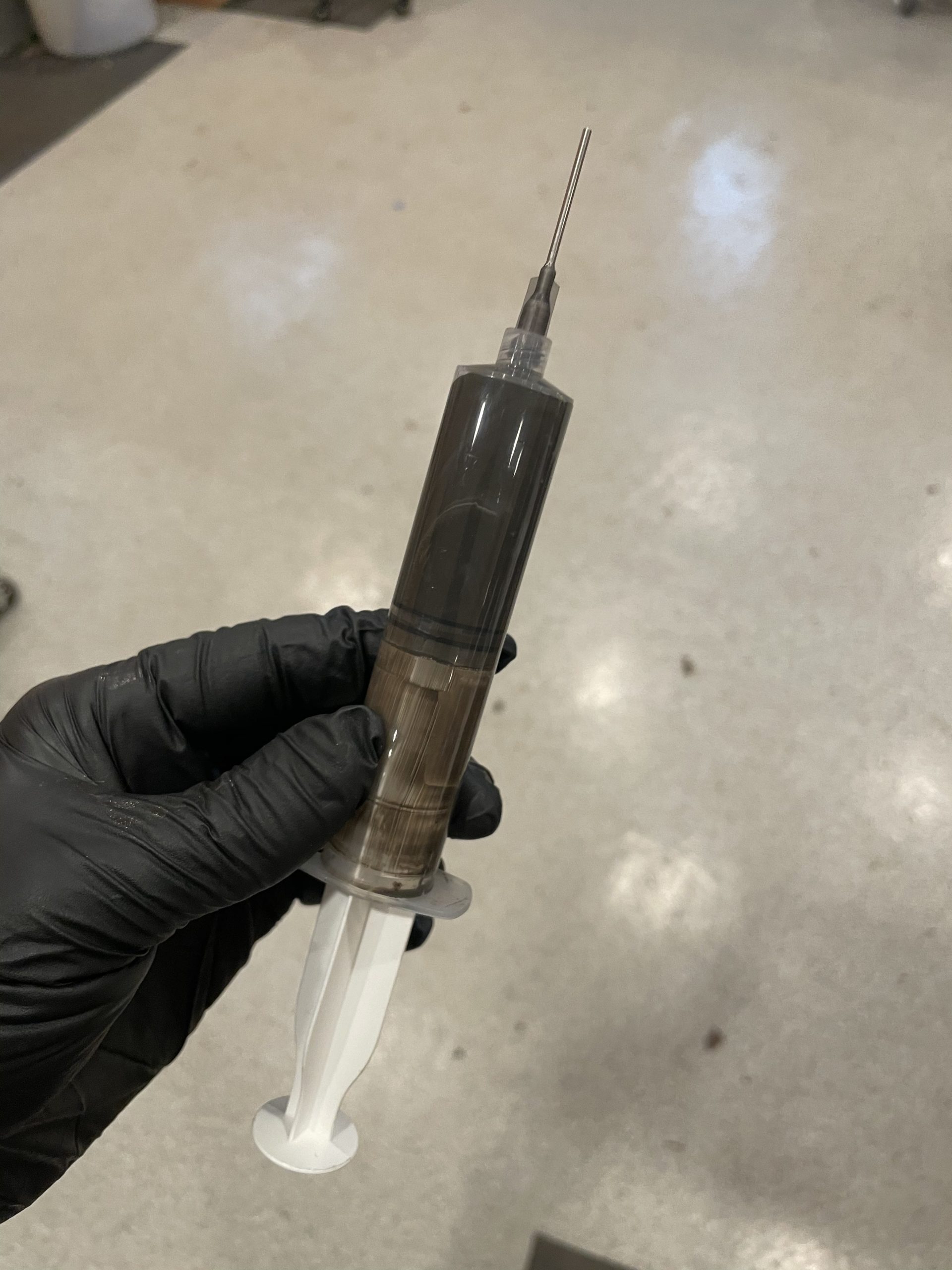

The Fuel tanks are typically the most dreaded part of the build because of the need to mix fuel sealant and properly apply and rivet the mating parts to ensure no leaks. For me, it was the longest section of the build so far at 130 total hours that spanned from April – December 2020. These are my “Quarantine Tanks” as they were built (slowly) throughout these past 9 months.

Part of the reason why this section spanned such a long timeframe is that building was a last priority while dealing with the implications of Covid on daily life. For the three months of August, September, and October, I was only able to build a total of 22 hours. Also, because of having to mix Fuel Selant in amounts useable in a work session, I typically needed 4 hours of dedicated time to work without interruption which was often difficult to do.

However, after testing the tanks following factory procedures of inflating the tanks to approximately 1 psi, using a balloon as an indicator and using soapy water along all rivet lines, i’m fairly confident the tanks are leak free! It will be some years from now until I truly know and have the tanks fully fueled up.

On a somewhat ironic note worthy of 2020, after being 95% complete building the tanks, Van’s Aircraft released a 2.5 hour video of best practices for building tanks! Gah! It was a bit painful to watch because I could see many areas I could have improved. The main lesson being in I likely used way too much sealant…which won’t hurt anything, is a bit of insurance, but adds a little weight to the plane. Oh well, next time 😛

Part 1: Prepping parts for assembly

Part 2: Riveting and assembling each tank

Part 3: Leak testing and attaching tanks to wing spars

Below is the time lapse of the 9 month(!) fuel tank assembly.

1 comment for “The long journey of building the fuel tanks”